Mineral

At Widyan, we source, refine, and supply high-purity industrial minerals engineered for consistent performance across glass, ceramics, construction, metallurgy, chemicals, and water treatment.

Why Widyan?

Uncompromising Quality & Purity

Careful ore selection: We partner with trusted quarries and validate each lot at intake to ensure low impurities and stable chemistry.

Refining & beneficiation: Multi-stage crushing, magnetic separation/deferrization, washing, drying, and precision screening deliver uniform particle size and low contaminants.

Tight QC at every step: In-house labs (XRF, sieve analysis, moisture/LOI checks) verify compositional targets and reproducibility batch after batch.

Application-ready grades: From fine powders to calibrated aggregates, we tailor grades for melting behavior, fluxing efficiency, whiteness, and rheology—so your process runs smoothly.

Decades of Know-How

For years our team has supplied leading manufacturers throughout MENA and beyond. We understand kiln behavior, furnace constraints, glaze chemistry, filtration needs, and cement/lime kinetics—and we align specifications with your line conditions, not just a datasheet.

Our Product Range

Sodium Feldspar (Albite)

A high-consistency flux for glass and ceramics that lowers vitrification temperature, enhances strength, and improves chemical resistance.

Typical applications: porcelain & sanitaryware, wall/floor tiles, container glass, enamel coatings.

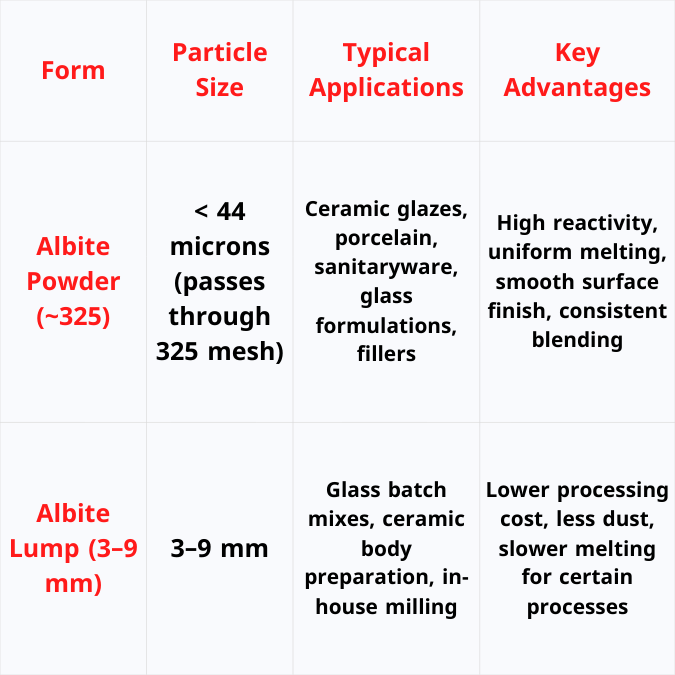

Available forms:

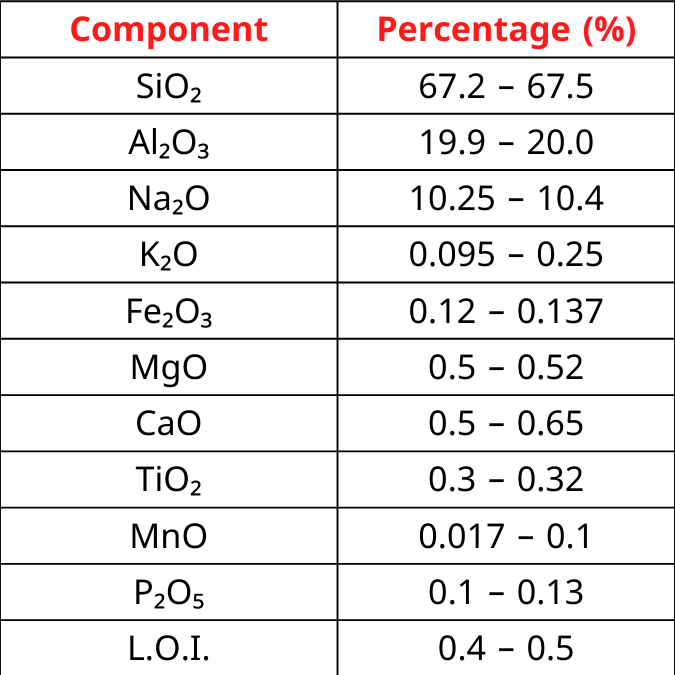

Chemical Analysis:

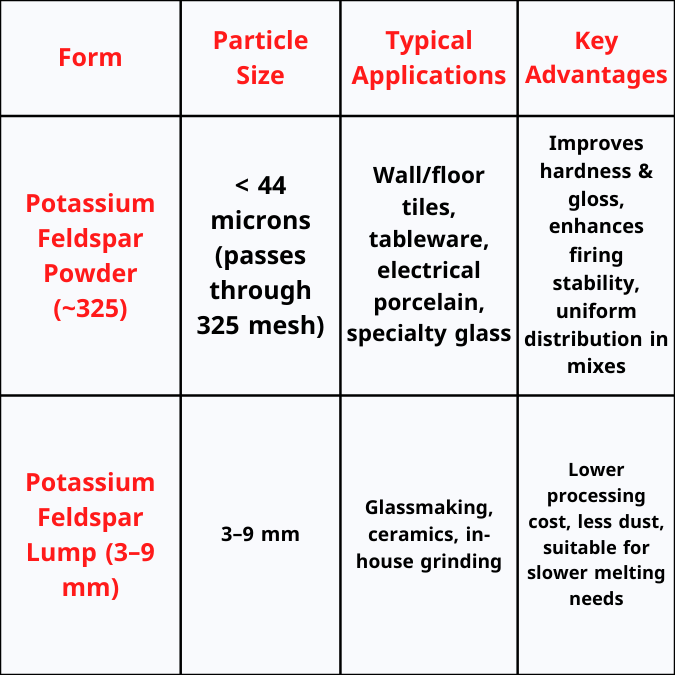

Potassium Feldspar

Preferred in many ceramic bodies and glazes for hardness and gloss, with excellent firing stability.

Applications: tiles, tableware, electrical porcelain, specialty glass.

Available forms:

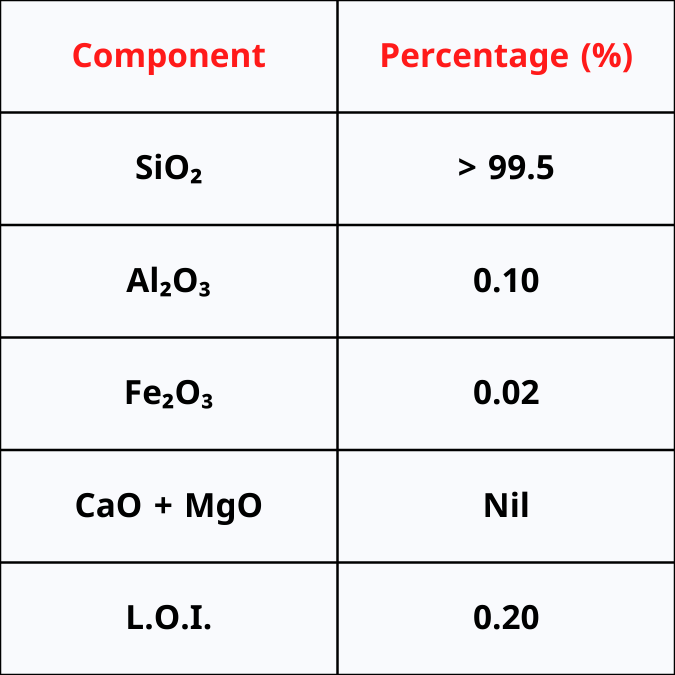

Silica Sand (Quartz)

High-purity silica with controlled granulometry for optical clarity and thermal stability.

Applications: flat/float glass, foundry molds & cores, silica flour for paints & polymers, water filtration.

Available forms: glass-grade and foundry-grade sands; multiple AFS/mesh cuts.

Chemical Analysis:

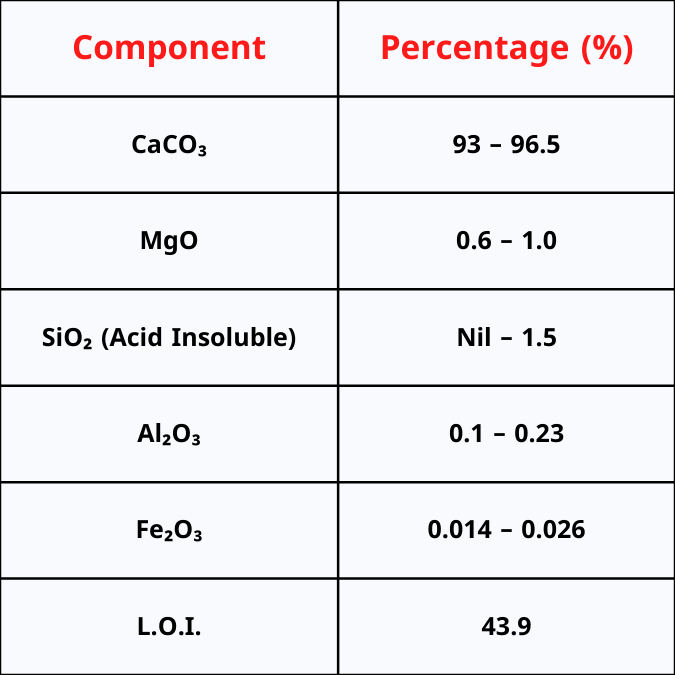

Limestone / Calcium Carbonate (CaCO₃)

Consistent CaCO₃ for cement, flue-gas treatment, steelmaking flux, and filler applications requiring brightness and low trace metals.

Applications: cement & lime, agriculture, plastics/paper/paints fillers.

Available forms: aggregate, ground (GCC), micro-ground.

Chemical Analysis:

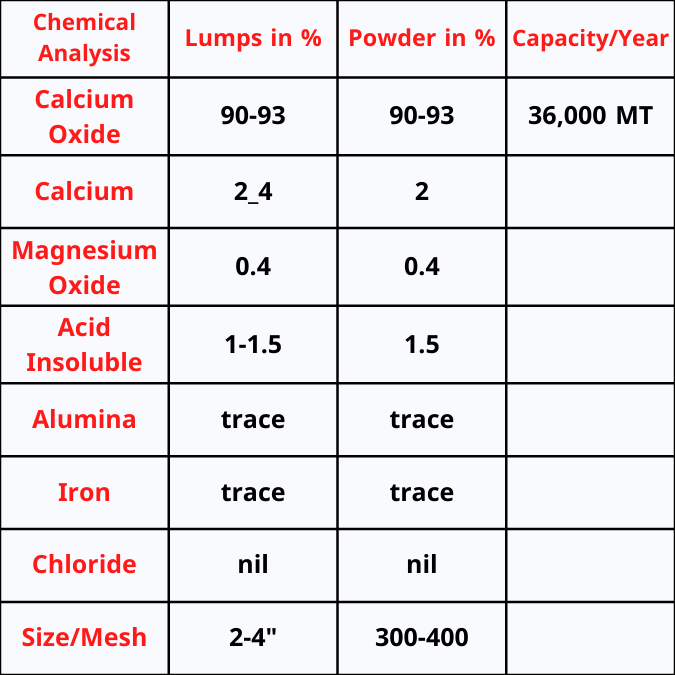

Calcium Oxide / Quicklime

Reactivity you can rely on—produced from selected limestone in modern kilns, then stabilized for safe handling.

Applications: steel refining, pH control, soil stabilization, flue-gas desulfurization, pulp & paper.

Available forms: lump, pebble, and ground quicklime; tailored reactivity profiles.

Chemical Analysis:

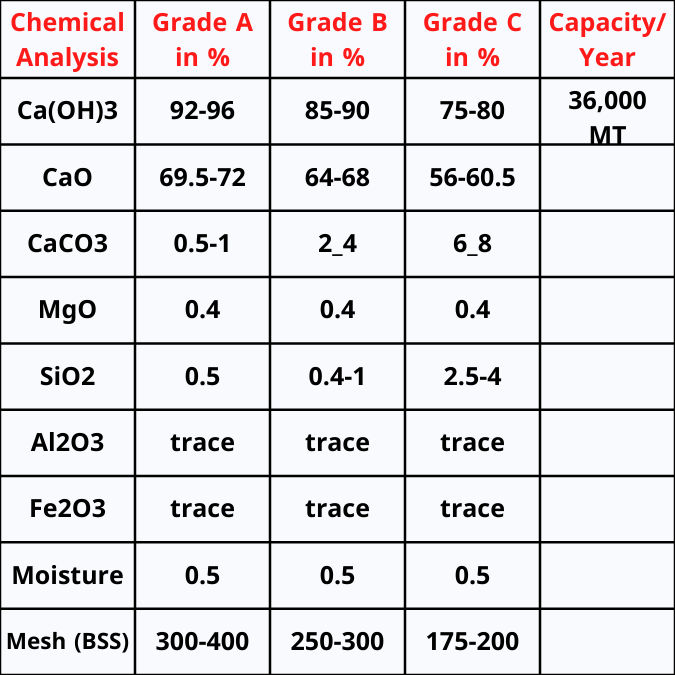

Calcium Hydroxide / Slaked Lime

Produced by controlled hydration for predictable rheology and pH.

Applications: water & wastewater treatment, sugar refining, mortars & plasters, environmental remediation.

Available forms: dry hydrated lime (powder), milk-of-lime (on contract).

Chemical Analysis:

How We Ensure Consistency

1. Source & Verify → geological assessment, intake sampling

2. Crush, Wash, Classify → remove fines/oversize and clay

3. Magnetic Separation/De-iron → reduce Fe and other metallic impurities

4. Dry & Mill → moisture control and particle engineering

5. Screen & Blend → tight PSD windows; application-specific blends

6. Final QC & Packaging → COA with every shipment

Packaging & Logistics

• Industrial sacks & big bags: 25 kg, 50 kg, and jumbo bags (≈1–1.5 t) with palletizing and stretch-wrap options.

• Bulk supply: silo/bulk truck and containerized loads for large users.

• Documentation: Certificate of Analysis (COA), Safety Data Sheet (SDS), and Technical Data Sheet (TDS) available for all grades.

• Lead times: Reliable production slots and export support from port to plant.

Industries We Serve

Glass & Foundry • Ceramics & Sanitaryware • Cement & Lime • Metallurgy & Steel

Chemicals • Water & Wastewater • Agriculture • Paper, Paints & Plastics

Sustainability & Compliance

We operate with responsible quarrying practices, water recycling in washing lines, and dust/particulate controls. Our products ship with clear handling, storage, and EHS guidance to support safe, compliant operations on your site.

Ready to Specify?

• Request COAs/TDS/SDS for your target grade.

• Ask about low-iron options, custom mesh/AFS cuts, and blend optimization for your furnace or kiln.

• Our technical team can benchmark your current feed and propose a Widyan grade that reduces waste and improves throughput.